Achievement Plan

| Improvement Area | 2023 | 2024 | 2025 | 2026 | 2027 |

|---|---|---|---|---|---|

| monthly handset sales plan | 46k | 82k | 115k | 165k | 230k |

| handset sales manpower | 32 | 38 | 45 | 55 | 60 |

| production manpower | 48 | 80 | 95 | 150 | 220 |

| Potential Cell Phone Dealer Coverage | 20 | 28 | 35 | 40 | 52 |

| Potential Cell Phone Retail Coverage | 10k | 12k | 15k | 18k | 22k |

| Service Center Increment | 30 | 32 | 35 | 38 | 40 |

2027

we will sale 2.3 lac Pcs handsets per month

2023

Our journey have started with 46k handset sales per month

To make our plan successful

We have established our own factory building at Narayanganj

Own 10 Storied Building

45k Sqft Production Space

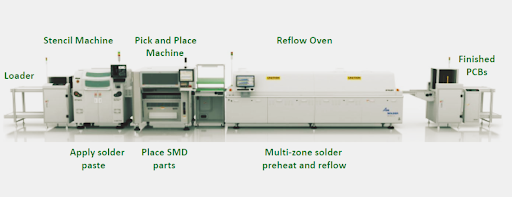

SMT Line

We have established a state-of-the-art SMT line with capacity of 40k units per day.

Assembly Line

Our assembly line can handle up to 30k feature phones and 10k smartphones daily.

Testing Facility

Comprehensive testing facility with automated and manual testing procedures.

Packaging

Modern packaging facility with capacity matching our production lines.

Factory Facility & Production Capacity

| Particulars | Current | Possible Expansion |

|---|---|---|

| SMT Line Capacity | 40k units/day | 80k units/day |

| Feature Phone Assembly | 30k units/day | 60k units/day |

| Smartphone Assembly | 10k units/day | 30k units/day |

| Testing Capacity | 45k units/day | 100k units/day |

| Packaging Capacity | 50k units/day | 120k units/day |

| Quality Control | 100% | 100% |

Assembly System and software tool

The production matches the MES system, the production slider has a display kanban, and the kanban displays the production status in real time.

IDH Assembly Process

Laboratory Facility

Perfect Lab Environment

We have inaugurated world class LAB environment in terms of humidity, temperature, sound, light & Dust free.

All Equipment's Availability

We are arranging all required machinery & equipment's as per BTRC & NBR Guideline.

Main lab testing as per quality checking

pressure test

to dial 1000 times phone call continuously on the automatic test software, if there is a problem, we must rewrite relevant softwares

anti-drop test

anti-drop test is conducted by special PPRT reliability lab. 0.5m drop test must be done 300 times for per surface, 2m drop test must be done 1 time for per surface

high/low temperature test

let the phone different temperature to test the adaptability of the phone. Low temperature is generally in the minus 20 degree celcius, high temperature is at around 80 degree celecius

pressure test

to dial 1000 times phone call continuously on the automatic test software, if there is a problem, we must rewrite relevant softwares

anti-drop test

anti-drop test is conducted by special PPRT reliability lab. 0.5m drop test must be done 300 times for per surface, 2m drop test must be done 1 time for per surface

high/low temperature test

let the phone different temperature to test the adaptability of the phone. Low temperature is generally in the minus 20 degree celcius, high temperature is at around 80 degree celecius

Our Quality Assurance Processes

SMT Facility